Biological wastewater

treatment solutions

Municipalities, communities and farmers face significant regulatory challenges and cost increases around their wastewater treatment. Triple-T’s TAYA solutions offer a new, cost-effective and sustainable alternative, transforming biotreatment of wastewater from a burden into an asset.

Our game-changing “fit and forget” solutions are based on gravel and plastic fixed film media biological processes, utilizing processes like passive aeration by atmospheric oxygen to treat domestic and livestock wastewater.

Leveraging our proprietary, eco-friendly TAYA technology, which significantly diminishes sludge, our smart and seamless solutions reduce sludge and handling, simplify operation and minimize labor, translating into significantly lower OPEX. Due to their high operational benefits, TAYA solutions outperform traditional intensive solutions. All our modular and turnkey solutions are provided as full-service projects, including engineering, construction, support, piloting, consulting and R&D.

With TAYA solutions, our customers enjoy easy, minimized operation and gain wastewater reuse autonomy, along with huge cost and energy savings and peace of mind.

All TAYA solutions are modular installations. Multiplying the number of units enables higher treatment volumes.

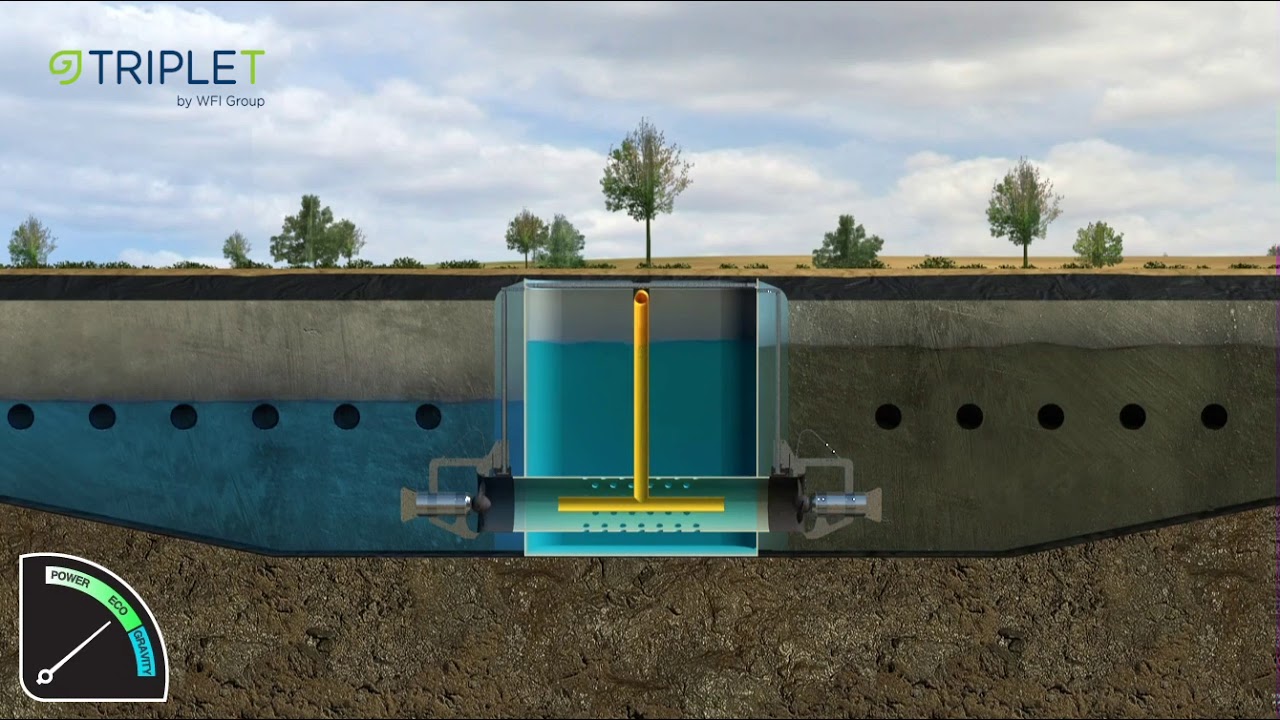

TAYA solutions are implemented in dual passive aeration units – basins filled with gravel media that are connected via a pumping chamber. The wastewater is constantly circulated between the two basins, alternately filling one basin and then the other. Each time a basin is filled, organic matter and nutrients are supplied to the biofilm growing on the media. Once drained, oxygen is supplied by passive aeration, for COD oxidation and nitrification.

The TAYA technology design and operation creates the right environmental conditions for simultaneous nitrification/denitrification (SND), so that both processes are accomplished in the same reactor. While nitrification occurs in the drain phase, denitrification is accomplished in the fill phase once anoxic conditions exist in the basin.